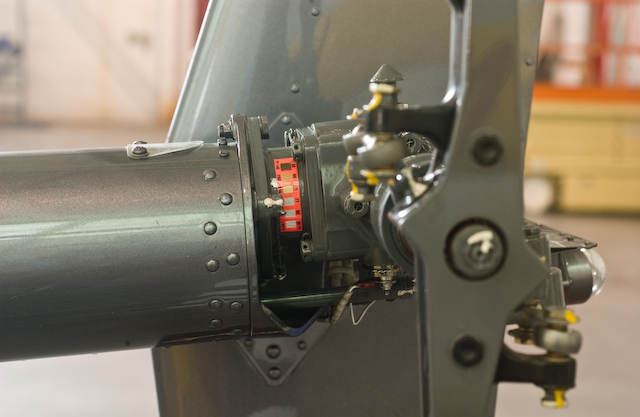

The tail rotor gearbox teletemp is positioned as in the photograph above. It's common to see discoloration of the upper temperature boxes, I assume from the exposure to UV light from the sun.

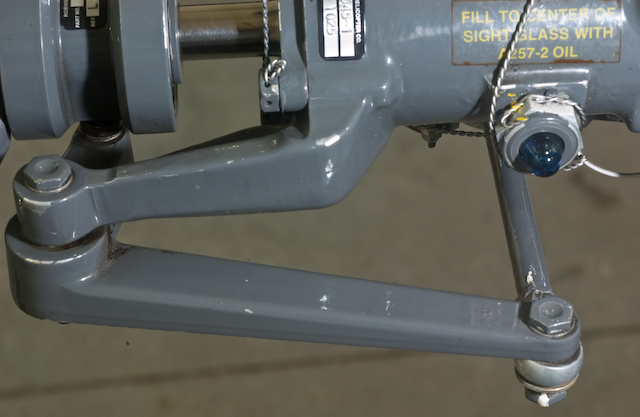

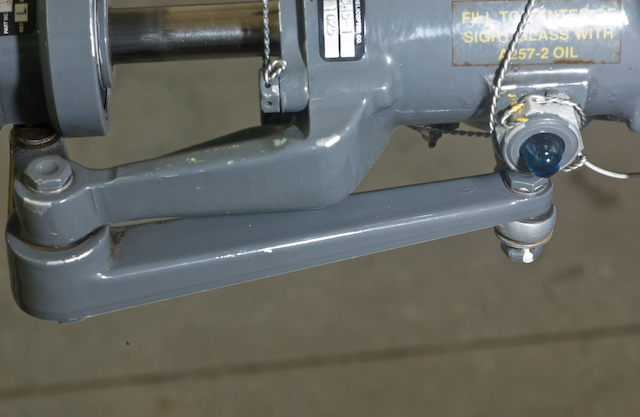

To check the tail rotor gearbox oil level, stand to the side and look sideways at the sight glass. You can see that the oil is blue, and you can see that the sight glass is about half full.

In cold climates, you should check this before you turn the rotor system, because otherwise the oil will collect on the gears and the sight glass will appear empty. When it is cold outside and the oil is thick, it can take many minutes before the oil drains off the gears and appears in the sight glass again.

The blades themselves are just aluminum skins wrapped over on top of themselves and bonded. If you look carefully near the tip, on the right hand edge (leading edge) you can see where the paint has been worn off by dust/salt/etc/ in the air. You should check that this erosion has not actually penetrated the surface of the blade - if so the blade needs to be replaced.

Check for any indication on the tip caps that the blade may have hit the ground or other objects. Look at the blade from several directions and make sure it has not been bent.

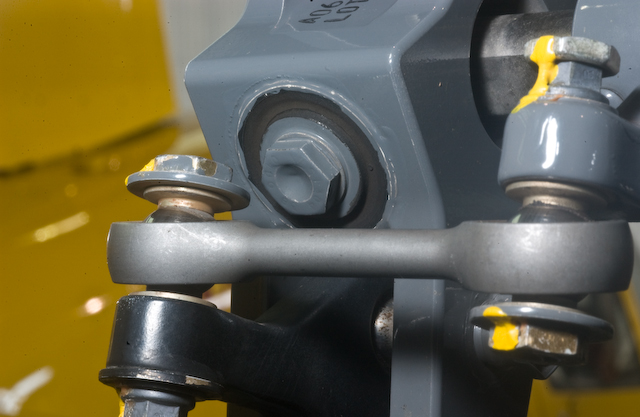

In the two pictures above, you can see how the pitch link rod end connects to the tail rotor.

On the right side, the pitch change mechanism acts as a swashplate, collectively feathering the tail rotor as commanded by the anti-torque pedals. The left edge is connected to the blade horn. You can see the spherical ball that the bolts go through, and this ball sits inside a race in the dog-bone shaped rod. Between the ball and the race is a teflon material to allow them to work freely.

The above picture shows the end of the pitch link connected to the tail rotor swashplate. This part moves only when you move the anti-torque pedals.

This picture shows the rod end which attaches to the tail rotor blade. The "rod" is a pitch link that transfers tail rotor pitch information from the tail rotor attachment assembly to the rotating tail rotor blades. The inner part of the rod moves when you move the anti-torque pedals. The outer part (pictured here) cycles each time the tail rotor completes one revolution (because the tail rotor flaps). Because of this, the outer rod end bearing wears out much faster than the inner bearing. When the outer bearing is reaching wear limits, the mechanic will typically flip it over, effectively doubling the life of the bearings.

Inside the rod end bearing is a teflon material which is what allows the ball and socket to smoothly move without any lubricant such as grease or oil. You may find some fine brown dust around the bearing - this is the teflon material that is wearing out. When enough teflon material wears out, the ball and socket become loose and you get excessive play in the control rod. You can check it by holding the rod and the blade horn (the black section in the photograph) and wiggling the two parts. As the bearing wears out, the horn will have more play.

In the previous picture, you can see that a bolt goes through the center of the pitch link rod end, through the blade horn, and into a nut. The bolt end is at the top in the picture, and the nut is on the bottom. The nut is a grey material, and below it you see the jam nut which is more of a gold color. The purpose of the jam nut is to prevent the nut from loosening. You can see in the picture that there is a stripe of yellow torque stripe going from the blade pitch horn, over the nut, and then over the jam nut. This lets you know that none of those components have rotated, and therefore that the nuts are still torqued tightly.

Another name for the jam nut is a "Pal Nut'.

In the picture agove, we are looking at the nut end of the teeter bearing bolt. A nut and a pal nut are under the white torque stripe paint. Each end of the bolt goes through a bearing which allows the tail rotor to teeter (flap) around the bolt. If the bearing were to fail and seize, the entire bolt might rotate along with the tail rotor flapping. This would quickly wear out the bolt and cause a failure.

You can see a ring of black material surrounding the bolt. This is some sort of rubberized material which prevents excessive flapping during startup and shutdown. One problems with it on preflight is that it masks the wear in the teeter bearings. In earlier designs, you could see the bearing and you could judge when the bearing was getting loose. That is more difficult now.

In this picture you can see the tail rotor pitch control bellcrank. When the pilot moves the pedals, the push/pull tube moves forward and back and operates the bellcrank. You should check that the bolts all have pal nuts (jam nuts) and that the torque stripe is unbroken. You should pull the bellcrank forward and back and listen to the noise coming from the tailcone. It is common to hear a noise that I can best describe as "wuuurp, wuurp" (this is the hanger for the push pull tube being excited) but you should not hear any metallic scraping noises.